Concrete as a building material has been used in a range of casting methods due to the variety of ways of working with the material. An array of application methods in the construction industry has been observed through the course of this research ranging from the traditional practice in third world countries to more up-to-date digital fabrication methods in workshops and research circles.

Disadvantages are noted on both ends of the spectrum. The gains of using certain methods of casting concrete are considered as the key factor of choosing the correct construction logistics. These gains are measured by first calibrating the design outcome. The construction industry is surrounded by a set of restraints, which could influence deriving to logical solution for constructing a certain space within available resources, time constraints and expertise in advanced construction.

Complex geometric solutions that often lead to fluid spatial design are hence burdened by the constraints of place, time and resources. This could potentially lead to the risk of the monopolization of novelty in the built environment due to the lack of precision, know-how and advanced tools in unspecialized environments.

The few architectural masterpieces that have over come the many difficulties of design and construction have often required unreasonable amounts of resources, materials and expertise. The results are spectacular environments, which hide behind ugly and excessive processes of formation. The complication and abundance of these processes, that often are an afterthought of the design process, habitually compromise the initial ideas imagined by the architect by untruthfully forcing materials into the complex geometries conceived earlier.

In order to achieve simplicity and truth in the process of constructing the spatial fluidity that we pursue in the course of this research, the process had to be inverted. The research aims at new construction method where materials assemble to perceived and controlled complex geometries, according to a design system that is the result of a thorough investigation of how these construction materials behave.

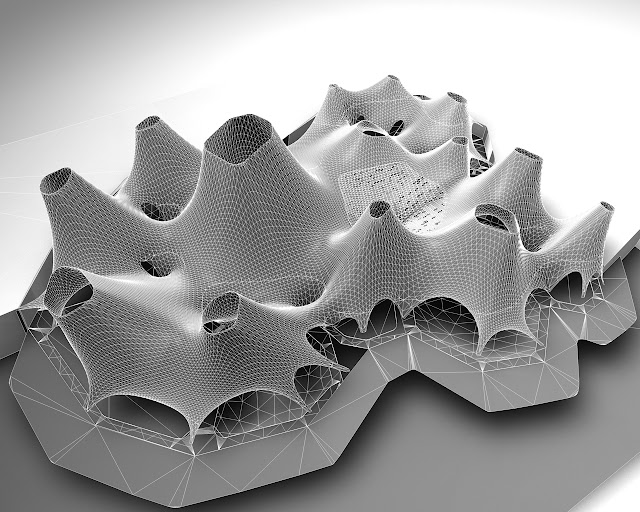

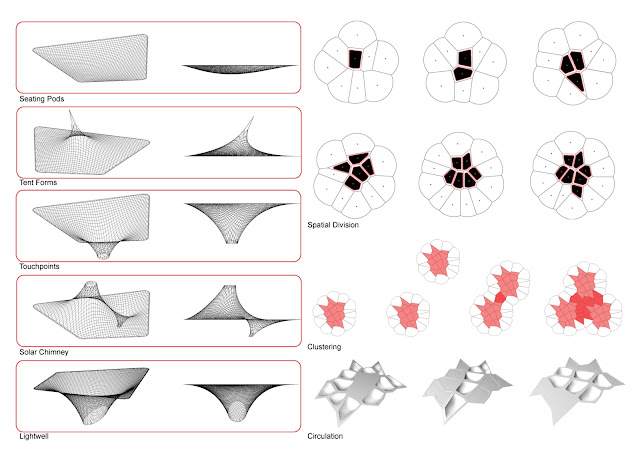

The design system generates digital outcomes that are based on limitations and possibilities of the material system investigations presented earlier.

Following through with the design evaluation, the presented series of diagrams explain the construction process through a 4- step summary of the procedures. The geometries of the iteration generated previously, aid in envisioning the construction logistics at full scale. The intention of these illustrations is to provide a simplified outline of the possible set of instructions to carry out the construction procedure.

The process starts by excavating the ground according to dimensions provided by the generated plan. Starting wit the outlines of that plot, the topography levels are achieved by excavating different areas at different rates. Further excavation can be done on the areas where the private recessed sub programs have to be introduced. The outcome is a topography that has differentiation in the levels according to the programmatic zoning rules.

To achieve the conical tent forms, industry standard hydraulic jacks are introduced at the centres of the polygons of the designated program areas. The equipment investigated to raise the fabric upwards should have the capacity to retract its height, to facilitate the movement underneath the structure as its being tensioned, and the removal of this equipment after casting. The possibility of creating specific equipment is a possible solution to tension and retract as well as spray compressive material. Such innovation in the construction procedure departs from standard methods and is relevant to the envisioned material system.

The fabric tensioning process ends with the formation of a tensile membrane enclosure, which is dependent on construction equipment for support. As discussed in previous chapters, the material system requires the stiffening of that membrane with compressive material layering, which enables the free form structure to become a structural shell. The layering process is an integral part of reaching the ultimate aim of a coherent systematic approach to spatial forming. The materials researched previously pertain different characteristics, and have to be dealt with in specific techniques to achieve a desirable result.

The construction process comes closer to completion by making sure that the roof form is covered with enough thickness of material to guarantee its handling of compressive forces, and aim at distributing these forces almost equally across the free form geometry. The last step of the sequence is to apply shot-crete that is reinforced with barchip fibre onto a steel mesh applied on the hardened Jesmonite and quad axial fibreglass mesh layers.